There are 5 common packaging paper types including corrugated paper, boxboard(kraft paper), whiteboard, white cardboard, gold and silver cardboard, etc. Different papers can be used in different fields due to different needs, to protect the goods.

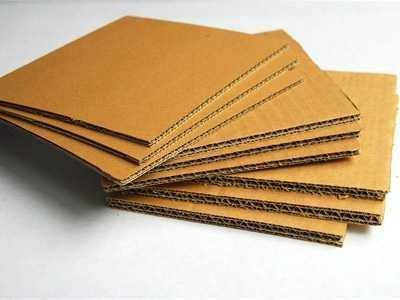

Corrugated paper

First, the corrugated paper is light and sturdy. Then, it has strong load, pressure, and moisture resistance. Most importantly, it is low in cost. Second, we can make corrugated paper into corrugated cardboard. And then to make various styles of cartons at customer orders and needs.

First, single-sided corrugated paper suits for a lining protective layer. And it is for commodity packaging or to make lightweight cardboard & pads. Then, it can protect the goods from vibration or shock during storage and shipping.

Second, three or the five-layer corrugated paper is used to make sales packaging of goods. Third, seven or eleven-layer corrugated paper works for making packaging boxes. Meanwhile, we also use it to make furniture or large household appliances.

5 packaging paper types of corrugated paper

According to the strength, corrugated paper can be divided into 5 categories: A flute, B flute, C flute, E flute, and F flute.

How to choose the corrugated paper?

- In general, corrugated paper made of A-type flutes has better buffering and elastic properties.

- The B-type flute has good stability, a smooth surface, and can withstand high plane pressure. So it is suitable for printing and used for outer packaging.

- The C-type flute is second to the A-type flute.

- E-type flute is thin and dense, and the printing effect is better. But the strength is poor, and it suits exquisite inner packaging.

Boxboard

Boxboard paper is known as Kraft paper. We can divide it into three grades: excellent products, first-class products, qualified products. Kraft paper is tough and cheap, with good folding resistance and water resistance.

Besides, we use it for making shopping paper bags, envelopes, cement bags, paper boxes, etc. Also, it suits food packaging paper. The texture of the paper must be tough. In addition, it must have high water resistance.

Whiteboard

There are two categories of whiteboard paper. One is for printing, which means “whiteboard” for short. And the other category is writing paper that suits whiteboards.

The fiber structure of whiteboard paper is uniform. And the surface layer has the components of filler and sizing material. So, the texture of the cardboard is a little tight. And the thickness is uniform.

Difference between whiteboard paper and coated paper, offset paper

The difference between them is that the paperweight of whiteboard paper is heavy. Its paper is thicker and the color of the front and back is different. Whiteboard paper is gray on one side and white on the other. So, it is also known as gray-coated white.

Application of whiteboard paper

Whiteboard packaging paper type is white and smooth and has uniform ink absorption. And, it is stronger and has better folding resistance. But, its water content is high. So, it suits for single-sided color printing. And then we make it into cartons for packaging. Or use it for design and handmade products.

White cardboard

White card paper is a single or multi-layer bonded paper made of bleached chemical pulping. In general, it has 3 types: blue & white single and double-sided coated cardboard; white-coated cardboard; gray coated cardboard.

Blue and white single and double-sided coated cardboard

We divide it into sika paper and copper sika.

Main uses:

Sika paper is mainly used for business cards, wedding invitations, postcards, cards, data cards, etc.;

Copper Sika is ideal for book and magazine covers, postcards, cards, wedding invitations. At the same time, we use it for hang tags, cosmetics, paper boxes that need beautiful printing.

Making hang tags

- Plate making;

- Printing;

- Mounting paper;

- UV;

- Film; (single-sided bright film; double-sided bright film; single-sided matt film; double-sided matt film);

- Concave and convex;

- Cutter;

White-coated cardboard

It is perfect for making more advanced cartons and vacuum blister packaging. So, the paper surface must have high whiteness and a smooth paper surface. Then it needs to have good ink acceptance and good gloss.

Gray coated cardboard

Its top layer uses bleached chemical pulp. And it is suitable for color printing of high-grade cartons. Thus, we often use it to make various cartons and hardcover book jackets.

Gold and silver cardboard

Gold and silver cardboard is a printing process that uses for color printing packaging. It belongs to emerging anti-counterfeiting skills in the industry.

Applications

The paper is ideal for color printing packaging. It is suitable for box-making and carton-making printing and packaging. Such as cigarettes, alcohol, food, cosmetics, toothpaste boxes, medicine, and gifts.